Over the past decade, regulations and technologies used in fire protection systems have undergone significant changes. This means new safety standards need to be applied to your factory, especially if it’s more than a decade old.

In this article, we’ll guide you through the latest developments in safety standards and the signs that you should immediately conduct a factory fire protection system audit.

Regulatory and Technological Changes in the Past Decade

The rapid development of technology has played a significant role in changing fire protection system standards, from the use of AI-based sensors that accelerate fire detection to the integration of the Internet of Things (IoT) for better monitoring and data analysis.

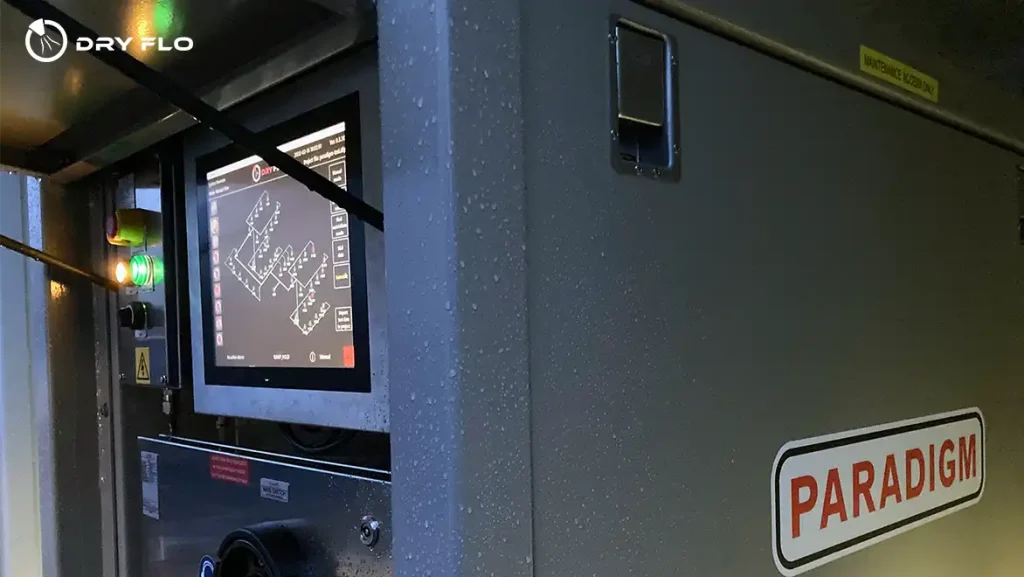

The emergence of these new technologies has given rise to many innovations, such as Dry-Flo®, a system developed by a Dutch company, Paradigm, that allows fire suppression system testing without the need for water discharge.

Honeywell has also introduced AI-based sensors that can analyze environmental data to predict fire risks more accurately, and other notable new technologies.

These emerging innovations have led several international associations to revise their safety standards, including the 2025 edition of Code 72 of the National Fire Alarm and Signaling Code from the National Fire Protection Association (NFPA).

This latest edition includes several important modifications regarding fire protection system installation that you should be aware of:

- Increased cybersecurity requirements

- Increased smoke detector installation requirements, including the creation of an emergency control device interface that can connect control equipment with detection systems, such as ventilation systems.

- The introduction of Restricted Audible Mode Operation (RAMO) notifications, suitable for facilities sensitive to loud sounds and noise. This system can visually detect risks using low-frequency sounds

When Should You Audit Your Fire Protection System? Check The Signs

For optimal maintenance, fire protection systems should be audited monthly, quarterly, and annually. Or if you find any of these three signs, your factory’s system is outdated and needs immediate upgrading.

If You’re Still Using Old Detectors

The first sign is the use of old detectors, such as ionization smoke detectors, and also detectors that are not integrated with control equipment. If left unchecked, this will take longer to detect a fire and lead to a slower response.

There Are Rusty Pipes and Leaks

The second most obvious sign is a leaking pipe that is mostly caused by water-corroded pipes. Leaking pipes not only delay fire response but also hinder normal factory performance.

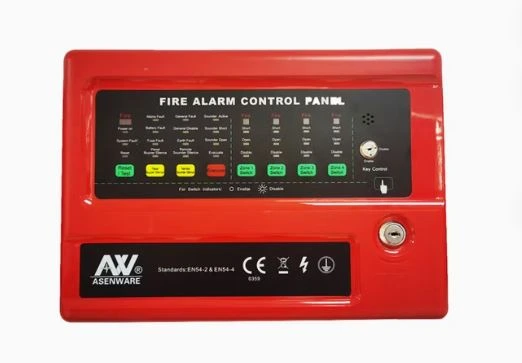

If You’re Still Using Conventional Alarm Panels

If your factory is expanding due to increased production, you need to upgrade your alarm system. This is especially true if you have more warehouse space for storing goods that are prone to sparks.

Small factories typically use conventional alarms that can only detect specific zones. As your warehouse expands, you need an addressable alarm system that can detect fires more accurately.

Audit Process by a Fire Engineer: What Should be Checked?

If your facility exhibits one or all three of these signs, you need to immediately call an expert for an audit. The following will be inspected during the process.

Building Structure

The first thing a fire engineer will inspect is the building structure, from the building materials to the surrounding systems, such as the electrical and ventilation systems. They will ensure that every element is safe and that there are no structural defects that could potentially ignite a fire.

Danger Zones and Storage of Flammable Items

Second, the technicians will also map fire-prone zones and storage areas containing flammable items. They will ensure that these items are stored according to safety standards and are located away from potential fire hazards.

Fire Equipment

A fire risk assessment is incomplete without inspecting fire protection equipment, such as alarm systems, sprinklers, hydrants, etc. At this stage, the technicians will conduct an in-depth audit of each system.

For example, a penetrant test and leak test are performed on the hydrant system, or a remaining life assessment is performed to detect corrosion in the pipe installation and estimate its remaining service life. All of this is done to ensure that each system is safe and meets applicable safety standards.

Fire Evacuation Routes

The next step is to check whether you have implemented the right fire evacuation routes. This includes putting on proper emergency signage, installing emergency lights, and selecting appropriate assembly points. If you’re unfamiliar with these, learn how to design effective evacuation routes in our previous article.

Fire Drill Training

Finally, fire engineers should also ensure that you regularly conduct fire drill training for factory workers. In addition to proper fire safety installations, another important preventative measure is familiarizing building occupants with fire drills with emergency responses in the event of a fire.

The Most Effective Upgrade Recommendations to Improve System Reliability

Upgrading your system doesn’t have to be about following the latest technology trends like AI or IoT; it should rather be based on your factory’s needs. However, installation efficiency and speed of fire detection remain key considerations.

For example, if you experience a pipe leak and your factory system is shut down for several days, you can use Victaulic’s FireLock™ product, which features mechanical connection components.

This product can speed up the installation process so that repairs don’t delay production for too long. Or, if you need a fire extinguisher that can inhibit combustion, Victaulic also offers the Vortex™ product, which can protect assets without residue.

Conclusion

Given the ever-evolving nature of technology and safety standards, auditing your factory’s fire protection system is crucial, especially if your facility is more than ten years old and has undergone numerous changes in building layout.

Lumeshield offers trusted fire risk assessments from a team with over a decade of experience in the field. We will conduct a comprehensive audit in accordance with the latest industry standards, including those of international associations such as NFPA and FM Global.

We have experienced every phase of technological development in fire safety, giving us the insight to provide system recommendations tailored to your facility’s needs. Contact us for a direct audit from the experts!