Storage facilities with high rack systems face a significantly higher risk of fire. Relying solely on conventional fire protection systems is not enough to ensure safety and compliance.

In this article, we’ll explore why a standard fire sprinkler for high rack storage may not provide adequate protection. Instead, we’ll introduce the ESFR (Early Suppression Fast Response) fire sprinkler—a system specifically engineered to suppress fires rapidly in high rack environments—and explain why it is essential to involve professional fire engineers in its design.

The Danger of the Chimney Effect in High Rack Storage

The chimney effect (stack effect) is one of the most critical problems that can occur during a fire in high rack storage facilities. This phenomenon happens when smoke, heat, and toxic gases generated by a fire rapidly rise and spread toward the upper sections of the structure. These hot gases then escape through gaps or roof vents, creating a chimney-like flow pattern.

The danger escalates quickly when this happens. The chimney effect allows fire and heat to spread vertically at a rapid pace, increasing the risk of the fire engulfing the entire storage area. As a result, the blaze becomes significantly harder to control.

The rapid vertical spread of fire also increases the risk of structural failure in high rack storage facilities. Steel components expand and lose their mechanical strength when exposed to high temperatures. Columns, beams, and connections that support vertical and lateral loads may weaken or collapse once the heat reaches critical levels.

Why Standard Fire Sprinklers Are Not Effective for Your Storage Facility

Considering the high level of fire risk, relying on a standard fire sprinkler system as your primary fire protection solution in high rack storage is often ineffective.

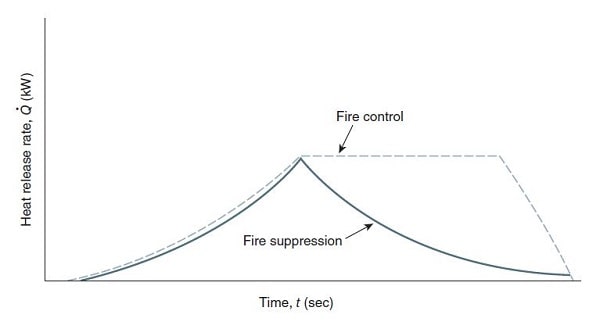

Standard fire sprinklers are designed to control the spread of flames rather than suppress them completely. The activation and discharge rates are slower, making it more suitable for smaller storage facilities with lower fire hazards.

This approach falls short when applied to high rack storage, where the fire risk is significantly greater. These facilities typically feature steel racks that can reach heights of over 12 meters. Once a fire ignites, it can spread rapidly in a vertical direction—making standard systems insufficient to contain or extinguish the flames.

What Is an ESFR Sprinkler and How Does It Work?

For high rack storage, the most effective automatic fire protection solution is the ESFR (Early Suppression, Fast Response) fire sprinkler.

This system is specifically engineered to provide a rapid response and early suppression when a fire is detected. Unlike conventional sprinklers, an ESFR fire sprinkler for high rack storage is designed to actively suppress and extinguish the fire at its source—preventing it from spreading and minimizing potential damage from the very beginning.

How ESFR Fire Sprinklers Work?

ESFR (Early Suppression, Fast Response) fire sprinklers are far more sensitive to heat compared to standard sprinkler systems. When the surrounding temperature reaches the activation threshold — typically between 68°C and 93°C (155°F–200°F) — the heat-sensitive element inside the sprinkler head bursts, triggering the system to activate.

At that moment, the ESFR fire sprinkler immediately releases water at high pressure and flow rates. The system produces large, forceful water droplets designed to penetrate flames, and suppress fire quickly and effectively.

These sprinklers are commonly used in areas with a high risk of fire, such as:

- High rack storage facilities containing flammable goods,

- Distribution centers, or

- Industrial buildings handling high-risk materials.

The widespread use of fire sprinklers for high rack storage is due to their distinct advantages:

- Fast Response: Activates more quickly than standard sprinklers, effectively suppressing fires in the earliest stage.

- Powerful Suppression: Delivers a high volume of water in a short time to extinguish fires efficiently.

- Flexible Application: Ideal for buildings with high ceilings and complex storage layouts, including large storage areas and distribution hubs.

- Fire Containment: Early suppression minimizes the spread of fire, protecting both people and property from severe damage.

ESFR vs. Standard Fire Sprinklers: Key Differences

Fire sprinklers for high rack storage, particularly ESFR (Early Suppression, Fast Response) systems, are significantly different from standard fire sprinklers — especially in their hydraulic design, pressure requirements, and water flow rate. These differences directly affect how each system discharges water and suppresses fire.

An ESFR fire sprinkler is designed with a high K-factor, allowing it to deliver greater water pressure and higher flow rates. As a result, the sprinkler produces larger water droplets with stronger momentum, enabling rapid and powerful fire suppression. The system requires robust piping and pumping infrastructure that can support the increased pressure and water volume.

Meanwhile, a standard fire sprinkler has a simpler hydraulic design with lower water pressure and flow rate. Its smaller K-factor results in finer water droplets and gentler spray characteristics. Standard sprinklers are typically used to control the spread of fire, rather than to fully suppress it, making them suitable for areas with lower fire risk.

To help you better understand the difference between both types, here’s a quick comparison:

| ASPECT | ESFR FIRE SPRINKLER | STANDARD FIRE SPRINKLER |

| Water Pressure | Higher | Lower |

| Water Flow Rate | High | Low |

| Droplet Size | Large with strong momentum | Smaller |

| Purpose | Fast suppression | Fire spread control |

| K-Factor | High (e.g., K=14) | Lower |

| Hydraulic System Complexity | More complex; requires stronger pumps and pipes | Simpler design |

The Importance of Proper Hydraulic Design by Professional Fire Engineers

Designing a fire sprinkler for high rack storage requires far more than just installation — it demands precise hydraulic system engineering. A small miscalculation can lead to serious consequences, such as insufficient pressure to activate sprinklers or excessive water usage that reduces system efficiency.

The hydraulic design process includes calculating water pressure, flow rate, friction loss, and optimal water distribution across every sprinkler head. Each parameter must be measured with accuracy.

To ensure accuracy and compliance with international standards, it’s essential to work with a professional fire engineer. Trained experts ensure the system design meets both technical safety requirements and legal regulations, guaranteeing that your fire protection system performs effectively when needed most.

At Lumeshield, we provide Fire Protection System Design services for storage facilities — including maintenance and upgrades for fire sprinklers in high rack storage systems. Just like you, we believe fire safety is not merely a formality — it’s a responsibility.

For over a decade, Lumeshield has upheld the principle of #SafetyThroughDesign. Our team of certified fire engineers develops, validates, and reviews comprehensive fire protection blueprints in accordance with NFPA, FM Global, and SNI standards.

While accidents can’t be predicted, fire risks can always be prevented. Contact us today to secure your high rack storage facility with a reliable, expertly designed fire protection system.